The BrewIQ System

Offering fermenters complete control at every step of fermentation. BrewIQ (formerly BrewMonitor®) replaces ad hoc sampling and testing with fully automated, live-streamed fermentation monitoring and analysis, making product quality and assurance better than ever.

Impact Process

- Continuous sampling and analysis

- Monitor tanks from any PC, tablet, or smartphone

- Receive preemptive alerts to fix variations

- Determine fermentation completion with confidence

Improve Product

- Measure and benchmark your beer

- Optimize tank time with real-time analysis and remote access

- Better understand your beer’s progress with information on dissolved oxygen, pH, gravity, pressure, temperature (ambient and fluid), and conductivity

Increase Profit

- Improve operational efficiency

- Decrease labor costs

- Eliminate unnecessary tank time

- Manage inputs and ingredients efficiently

- Increase product quality and consistency for greater market success

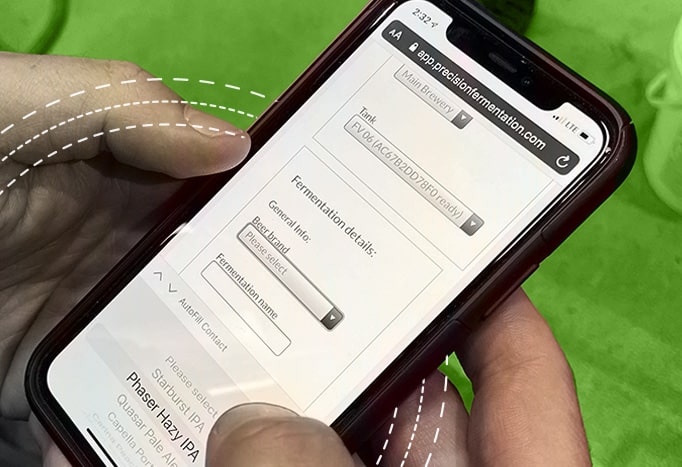

Real-Time Fermentation Analysis with BrewIQ Dashboard: Incredible Insights, Always at Your Fingertips

The BrewIQ Dashboard can be accessed remotely from any internet-connected device, providing instant visibility into your product quality.

- Remotely monitor DO, pH, gravity, pressure, temperature (fluid and ambient), and conductivity—all from a unified dashboard

- Quickly check the progress of all active fermentations

- Batch-to-batch trends: Easily compare multiple batches—past or present—for insight into your ingredients, hardware, and methods

- Yeast Vitality Trends: Instantly assess yeast health

- Centralized Data Management: Save, view, analyze, and communicate all collected data

Real-Time Intervention

The BrewIQ Dashboard sends automatic text or email messages if your fermentation goes beyond your set thresholds.

- Dissolved Oxygen

- pH

- Gravity

- Pressure

- Temperature (fluid and ambient)

- Conductivity

Unprecedented Visibility and Control

Instead of infrequent, unreliable manual testing, BrewIQ continuously provides deep insight.

- Monitor and analyze the environment within each fermentation tank with real-time continuous sampling

- Gain visibility into the progress of active fermentation and understand when/if you need to intervene

- Harness the power of in-depth, aggregated insights to improve control and repeatability

- Efficiently manage your staff’s time with instant views across all fermentations

- Save time and effort with 24-7-365 access to your tanks from any PC, tablet, or smartphone

- Save money by reducing fermentation errors to ensure product quality and yield is maximized

BrewIQ Fermentation Hub. One Device. So many possibilities.

Leveraging IoT Technology for Better Process, Product, and Profit

The BrewIQ System brings the “Internet of Things” to the brewing process by collecting and analyzing data from existing tanks and live-streaming it to your PC, tablet, or smartphone. The BrewIQ Fermentation Hub easily attaches to a tank and communicates critical fermentation measurements 24-7-365.