How to Aerate Your Wort for Efficient Fermentation

Are your beers getting stuck with stuck fermentations, off-flavors, under attenuation, or longer than usual fermentation times? Your solution could lie in a missing ingredient that you may have been taught to avoid like bugs on your clean side: oxygen.

Common belief misinstructs early stage brewers to keep oxygen as far away from post-boil wort and beer as possible, lest it develop staling off-flavors. The reality, however, is that during fermentation, yeast needs oxygen (02) to do its job … but only at the beginning.

Why Does Yeast Need Oxygen?

Yeast cells use oxygen to build pliant and permeable lipid walls, without which they can’t properly function or reproduce. Yeast with weak walls often acts sluggish and unresponsive, and its budding ability gets compromised in a way that threatens the viability of the crop.

When this happens, “Fewer cells have the glycogen reserves and cell membranes that can withstand the stress of fermentation and the alcoholic, low pH environment of beer,” write Chris White and Jamil Zainasheff in Yeast: The Practical Guide to Beer Fermentation.

To grow membranes strong enough to survive these stressors, cells produce sterols and unsaturated fatty acids (UFAs), which form through a complex chain of events that relies on oxygen to occur.

How Much Oxygen Does Yeast Need?

Yeast demands dissolved oxygen (DO) in 8-10 parts per million (ppm) to create sufficient sterols and UFAs, with the range accounting for differences in strain, temperature and specific gravity.

Lager yeast, with its already slow fermentation rate, calls for higher oxygen levels to keep things moving; yet conversely, because higher temperature wort is less gas soluble, it requires more 02, as well. And thanks to the higher pitch rate for high-alcohol beers, the higher the gravity, the higher the requisite 02.

It may take some trial-and-error to determine how long to aerate your high-ABV beer so you may want to try doubling the length of time at which you aerate your average-ABVs and work up or down from there.

Or you can modify calculations made by Danny Wang, co-founder and technologist at Fermly, that guide brewers to get 10 ppm of DO into a 10 bbl batch (brewed at sea level) by infusing 8.4 liters of 02 over an hour.

While White and Zainasheff caution against adding excessive amounts of 02, lest your beer develop an overabundance of fermentation byproducts, Wang says too much doesn’t typically pose a problem.

“The general consensus is that extra O2 won’t hurt your yeast, like *excessive* amounts of O2 will, but just having extra (even quite a lot more) isn’t going to hurt,” he emails. “Healthy yeast will uptake all available O2 in 3-9 hours anyways, and there isn’t too much to oxidize in wort during that time.”

When and How do I Properly Aerate (Oxygenate) My Wort?

Your sweet spot for aerating occurs just before pitching and just after chilling, with most commercial brewers hooking an aeration or oxygenation system up to their wort way to infuse their wort with air or pure 02.

(Note: though brewers informally use the word “aeration” as a catch-all, technically “aeration” describes the process of intentionally introducing air, while “oxygenation” applies to the addition of pure oxygen only.)

Aeration alone can prove ineffective, especially for higher-gravity brews, as dry air only holds 21% 0xygen by volume and can’t raise DO levels above 8 ppm. Both methods generally call for a brewer to connect either an aeration pump/filtration system, sterile air, an oxygen generator, or a canister of welding or medical-grade oxygen onto the wort way or the fermenter via an oxygen stone (AKA diffusion or sintered stone).

Explains beer journalist Nick Carr on Kegerator.com, “The porous stone creates thousands of very small bubbles. These small bubbles have a larger surface-to-volume ratio than bigger bubbles, allowing more oxygen to be absorbed on the way to the surface.”

Some brewers guard against contamination by using a filter with all air and oxygen products, and remember: it’s dangerous to use pure oxygen without a regulator or flow meter to monitor the high-pressure gas.

How to Track Dissolved Oxygen?

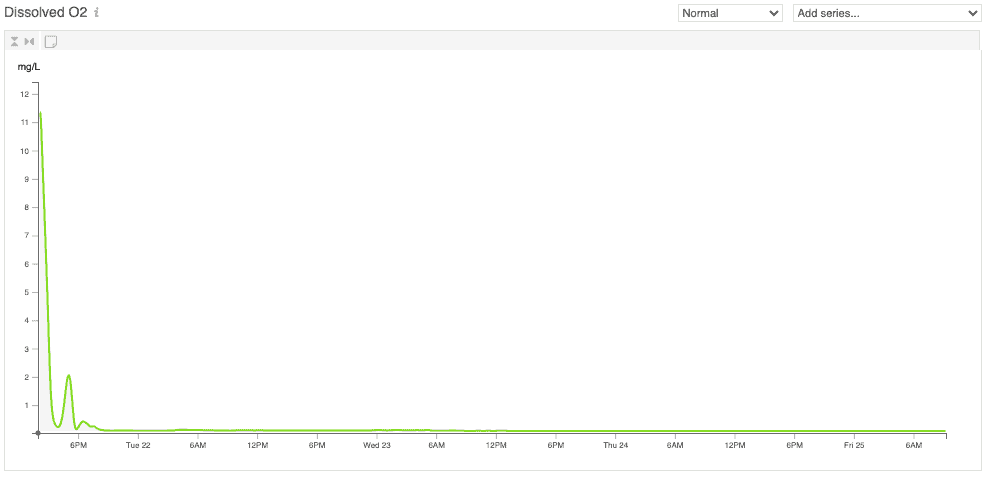

We already talked about yeast needing oxygen, but only in the beginning. The most prevalent way of tracking this is to monitor DO. A pitch of healthy and vital yeast would begin to change their environment as soon as they hit fresh wort. The graph below demonstrates DO of a typical fermentation.

As you’re adjusting methods to find your optimal aeration, it’s important to track both data and sensory notes. BrewIQ’s batch-over–batch analysis allows users to gather and compare fermentations with each other. Once you’ve determined your optimal method and fermentation, you can even benchmark these ideal fermentations to ensure consistency of process moving forward.

What Else Should Be Monitored?

In addition to sensory notes and DO, pH can be an excellent metric to track. pH can indicate acidity in your product—which not only is a good indicator of yeast activity and vitality, but also plays an important role in brand identity, microbiology, and sensory stability.

If you want to see more about how these metrics, along with others, work together over the course of a fermentation, schedule a demo for BrewIQ. Our platform gives brewers transparency at every step of the fermentation process to make better-informed, data-driven decisions.