BrewMonitor: A Look at Fermentation Data Curves – Fermenter Failures

BrewMonitor® offers your brewing team access to insight that has never been available before: high-resolution data from inside your fermentation tank, allowing you to track the progress of your fermentation, analyze results, benchmark future batches, and much more. The resulting graphs for each completed fermentation – dissolved oxygen, pH, gravity, pressure, temperature and conductivity – provide extremely clear views into the events that transpired and techniques that were employed. This series of articles shows examples of data curves from specific parameters, as they were recorded from the fermentation of various styles in different scenarios. These graphs are from actual fermentations, and offered as a look into how these conditions express themselves as measured data trends.

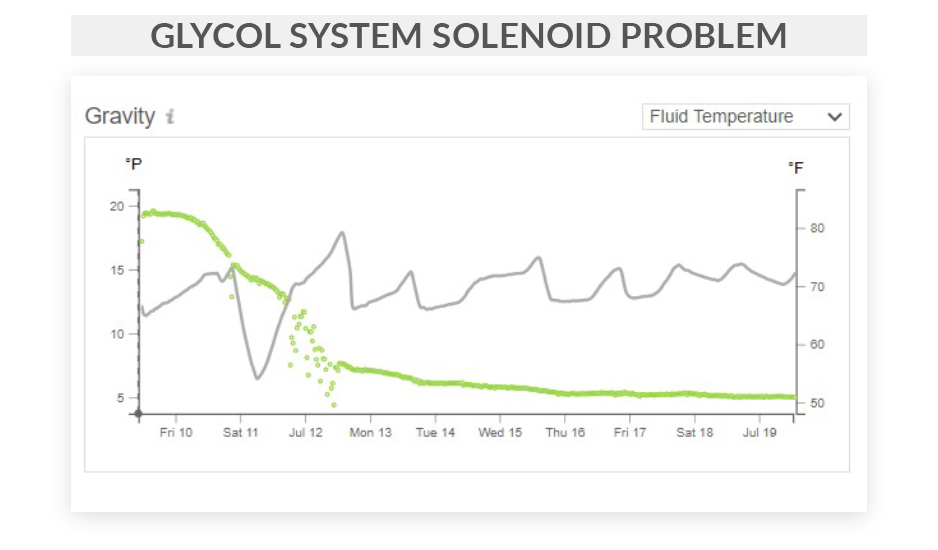

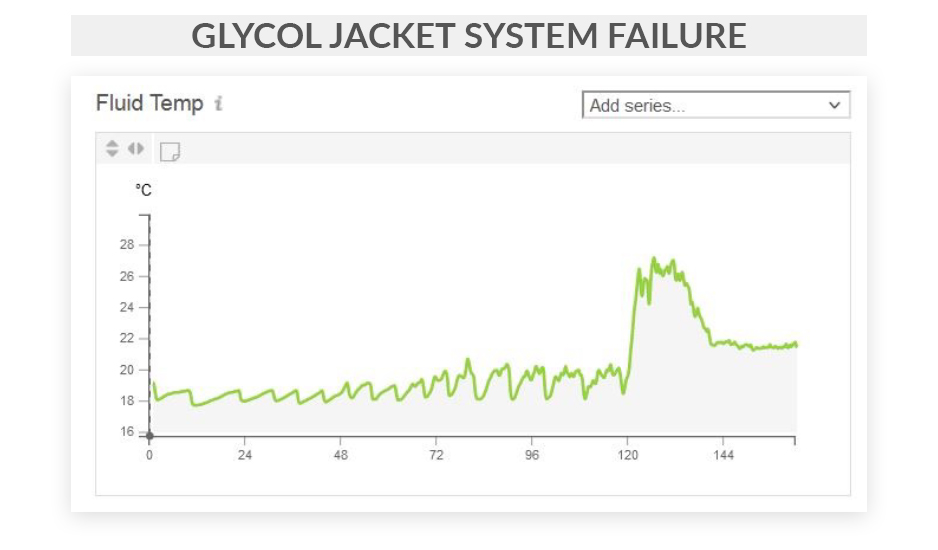

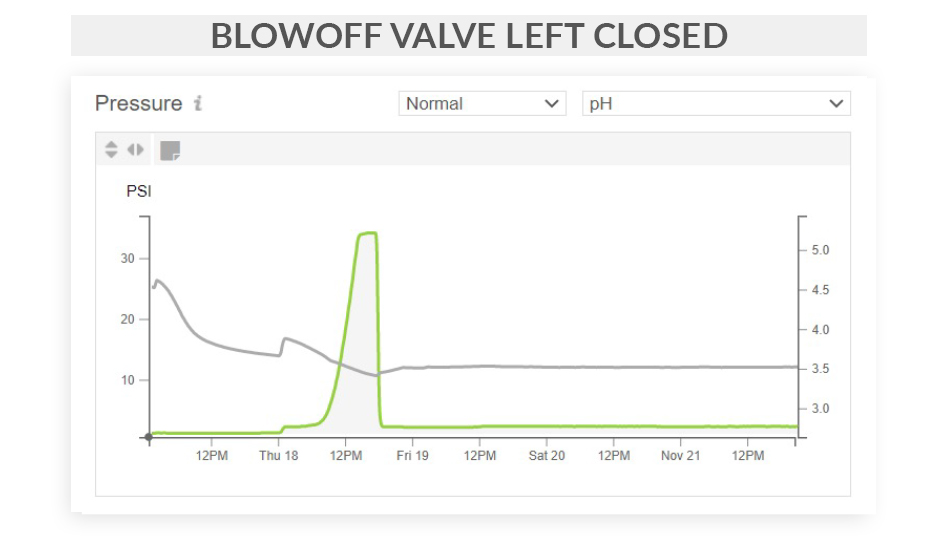

In this installment, we step through some examples of fermenter failures. Process or system malfunctions can come in many forms, including equipment failure and operator error. Detecting and solving these issues as early as possible can mitigate the impact they have on your final product, your production time, and your mental health!

See our earlier post on typical gravity curves »

See our earlier post on typical pH curves »

See our earlier post on typical conductivity curves »

However, in this case, the glycol jacket cooling system for this fermenter failed slowly over time. This can be seen in the fluid temperature graph; the “sawtooth” pattern begins to degrade as the glycol chiller fails to cool the tank back down to its set point every time the controller sends the signal. Ultimately, the cooling system failed completely and the tank experienced temperature free rise, along with three other active fermentations.

High pressures like this can cause multiple issues with the fermentation process. First, many fermenters are not designed to handle more than 29psi (2 bar). Even with a PRV in place to protect the fermenter, the speed at which CO2 is produced will outpace the rate of blowoff through the PRV. Second, yeast are particularly sensitive to large pressure swings. This can be seen in the pH (gray), as the sudden increase and subsequent release of pressure caused rapid changes in the metabolism of the yeast due to their stress response.

Free eBook: Leveraging Data-Driven Fermentation Performance Management

Can fermentation management be improved, as a process? This eBook explores, in detail, how fermentation performance data analysis helps elevate product and business outcomes in a modern brewery, whether brewpub, microbrewery or regional craft brewer.

You will learn:

- Day-by-day performance considerations – learned through the extensive examination of real-time fermentation tank data.

- Key recommendations from the Precision Fermentation science team at each major step of fermentation – “Day zero” (i.e. before you pitch your yeast), the first 24 hours, and day two through the end of fermentation.

- Best practices – Activity to watch out for, broken down by each key measurement – Dissolved oxygen, gravity, pH, pressure, internal/external temperature, and conductivity.

- Key findings that can help you solve problems and improve your results.